eTCP®

Next generation colorized, one-step technology delivering superior Type II protection on bare light metals for better performance and longer utility.

Available in Powder, RTU liquid, Touch-Up Pen and Wipe Kit.

CHEMEON’s suite of eTCP products retain electrical conductivity and are REACH, RoHS, WEEE and ELV compliant.

CHEMEON eTCP Touch-Up Pen is a DoD standard for small intricate part touch ups, MRO and field repair. Easy to use 1.5 oz pen applicator is in stock and ready to ship. For use on aluminum alloys, magnesium, IVD aluminum, zinc and zinc alloys, zinc-nickel and cadmium. CHEMEON Cleaner 4100 Pen, single step cleaner and acid activator, is also available.

Available Forms:

* TDS – Technical Data Sheet, SDS – Safety Data Sheet

CHEMEON Touch-Up Repair Kit (Wipes/Brush)

Discover Convenient Surface Repair Kit

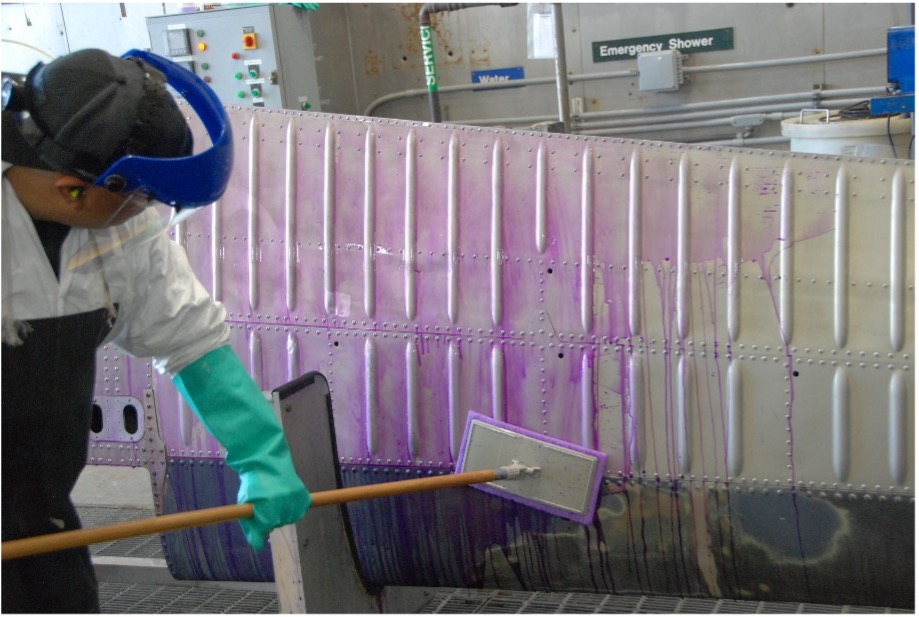

The CHEMEON Touch-Up Repair Kit provides MRO’s and field repair artisans precise and effective surface touch-ups in accordance with MIL-DTL-81706 specifications. Whether you’re removing oxides, fixing light scratches, or restoring surface integrity, this kit offers a convenient and reliable solution for professional-grade repairs.

Download How eTCP Came To Be PDF

Request CHEMEON eTCP info by providing info below.